Hi welcome to my blog!! here you will find a lot of interesting things about the marine engineering course at Unitec, I hope you enjoy as much we are enjoying been there learning lots of new things which we going to use to work in the marine industry.

Wednesday, March 30, 2011

Monday, March 28, 2011

Saturday, March 26, 2011

Making a Piston stop tool

Piston stop tool spec. sheet.

The Lathe

Measuring the external part, of the Piston stop tool

secure the metal bit.

Cutting to the spec. using the hacksaw

Ready to be worked, on the lathe.

Making the ends even.

done.

reducing the body to spec. from 26mm to 23mm

done

Measured

Measuring the steps

lowered from 23mm to 20mm.

Iternal thread

External thread

Internal drilling top end

Iternal drilling botton end

external body done.

Metal bit for internal body.

Reducing to specs. from 16mm to 8mm.

Starting the next stage, going from 16mm to 12.5mm.

Done.

Making the thread.

Thread ready.

Making the grip surface at the top of the bolt.

Grip surface done.

Making the grip surface to the external body.

Grip done.

Measuring the metal bit for the locking nut to the specs.

cuting to the spec. from 23mm to 18mm

Making the grip surface on it.

After drilled, taping it to make the internal thread.

using the hacksaw to cut the the nut.

Nut done.

Using the file to make a round edge

Piston stop tool done.

The Lathe work video..

Wednesday, March 23, 2011

"ILearning".. we are ready.. are you??

At unitec today doing the presentation on our metal project.

Every student in the room using their laptops, as required.

But...not for long time....Why??

Just four power points at the back of the room for 20+ students.

What can you do about it?????

Tuesday, March 22, 2011

Research on Brass(percentage+application).

Alpha brasses with less than 35% zinc, are malleable, can be worked cold, and are used in pressing, forging, or similar applications.

Beta brasses, with 45–50% zinc content, can only be worked hot, and are harder, stronger, and suitable for casting.

Cartridge brass is a 30% zinc brass with good cold working properties. Used for ammunition cases.

High brass contains 65% copper and 35% zinc, has a high tensile strength and is used for springs, screws, and rivets.

Low brass is a copper-zinc alloy containing 20% zinc with a light golden color and excellent ductility; it is used for flexible metal hoses and metal bellows.

Manganese brass is a brass most notably used in making golden dollar coins in the United States. It contains roughly 70% copper, 29% zinc, and 1.3% manganese.

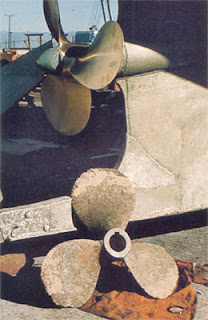

Muntz metal is about 60% copper, 40% zinc and a trace of iron, used as a lining on boats.

Nickel brass is composed of 70% copper, 24.5% zinc and 5.5% nickel used to make pound coins in the pound sterling currency.

Red brass is both an American term for the copper-zinc-tin alloy known as gunmetal, and an alloy which is considered both a brass and a bronze. It typically contains 85% copper, 5% tin, 5% lead, and 5% zinc.[24] Red brass is also an alternative name for copper alloy C23000, which is composed of 14–16% zinc, 0.05% iron and lead, and the remainder copper.[25] It may also refer to ounce metal, another copper-zinc-tin alloy.

Rich low brass (Tombac) is 15% zinc. It is often used in jewelry applications.

Tonval brass (also called CW617N or CZ122 or OT58) is a copper-lead-zinc alloy. It is not recommended for seawater use, being susceptible to dezincification.[26][27]

White brass contains more than 50% zinc and is too brittle for general use. The term may also refer to certain types of nickel silver alloys as well as Cu-Zn-Sn alloys with high proportions (typically 40%+) of tin and/or zinc, as well as predominantly zinc casting alloys with copper additive.

Subscribe to:

Posts (Atom)